SME shares operational considerations for LNG stations

Nowadays, natural gas, which ordinary people usually use for cooking and heating, is also used as vehicle fuel. Compared with diesel, natural gas combustion produces very little pollution and does not produce any smell or smoke. Another advantage is that vehicles that use natural gas as fuel produce three times less noise than those that use diesel, so the vehicle can drive in urban areas without noise pollution.

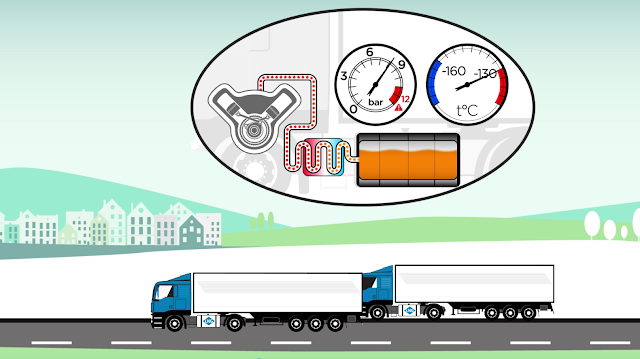

When natural gas is liquefied as fuel, it is commonly referred to as liquefied natural gas (LNG). Specifically, it is obtained by condensation at -162°C. Compared with the gaseous state, the liquid volume is reduced by about 600 times. In other words, fuel tanks with highly enriched natural gas can provide trucks with a distance of more than 1,000 kilometres. When the vehicle is running, natural gas is injected into the engine in a gaseous state and converted into the power required by the vehicle.

LNG is usually stored in double-layer insulated tanks on the side of trucks. The design features of these tanks can minimize heat transfer and can resist pressure when replenishing at gas stations.

Only by ensuring that LNG operates at saturation, that is, at a pressure of 8 bar and a temperature of -130°C, can it normally provide stable fuel supply to the engine.

Familiar with the above situation, let's look at the precautions when replenishing vehicles.

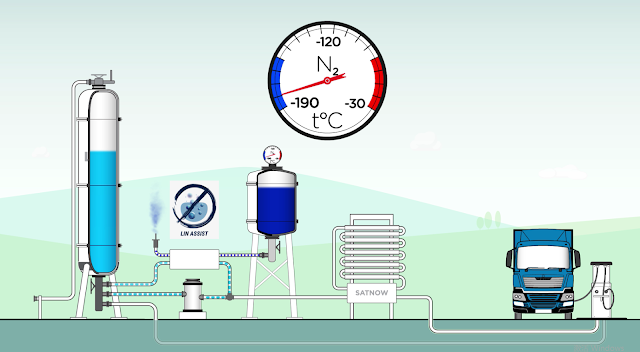

When the truck enters the replenishment station, the gas refuelling the station will first use the internal circulation heating pipeline to heat the ultra-low temperature LNG in the storage tank to -130°C.

Before refilling the vehicle, it is necessary to pre-cool the pipelines and equipment. The main method is to directly realize the LNG through the pipeline. However, this method will also partially vaporize the LNG itself, and these vapours are called "BOG"

Due to the heat exchange phenomenon, when BOG flows back into the storage tank, the internal pressure of the storage tank will gradually increase, and the temperature will gradually rise and produce more vapour. When the amount of heat and gas accumulates to a certain extent, the gas pressure gradually increases and rises, and finally suddenly erupts in the storage tank.

At the same time, the eruption of the liquid emptied the gas phase space in the pipeline, and the LNG liquid in the storage tank was quickly replenished into the pipeline, and the accumulation process of heated evaporation and vaporization of the liquid was restarted. After a period of time, the liquid would be formed again. The process of eruption, this process is called "Geyser".

If the "Geyser" phenomenon occurs frequently in the system, the resulting pressure shock and fluctuations will cause structural damage to the pipelines and valves of the storage tank, and at the same time, the evaporation of LNG in the storage tank will increase significantly. In the end, high-risk safety accidents and environmental damage and economic losses will become the worst results.

However, this situation can be avoided if the supply station is used frequently. This can reduce or even eliminate the cooling phase of more than 6 vehicles per hour and make the station reach a balanced state.

In order to minimize these restrictions, some companies provide a solution that specifically converts cold LNG to saturated LNG outside the storage tank as needed, instead of using an air vaporizer. So as to solve the limitation on time and replenishment frequency.

In addition, keeping the LNG storage tank at a low temperature can also slow down the pressure rise, thereby protecting the replenishment station from leakage. The specific method is that when the pressure in the storage tank is too high, the LNG will be sent to the heat exchanger, and liquid nitrogen will be used for cooling at a very low temperature. Through this method, the LNG storage tank can be kept at a constant temperature and pressure, and the potential safety hazard can be effectively eliminated.

The phenomenon of "Geyser" is one of the more common phenomena in LNG replenishment stations. The treatment of this phenomenon can already be classified as a conventional treatment method. With the improvement of equipment, the use of LNG energy will be more efficient and safer.